Core Technology

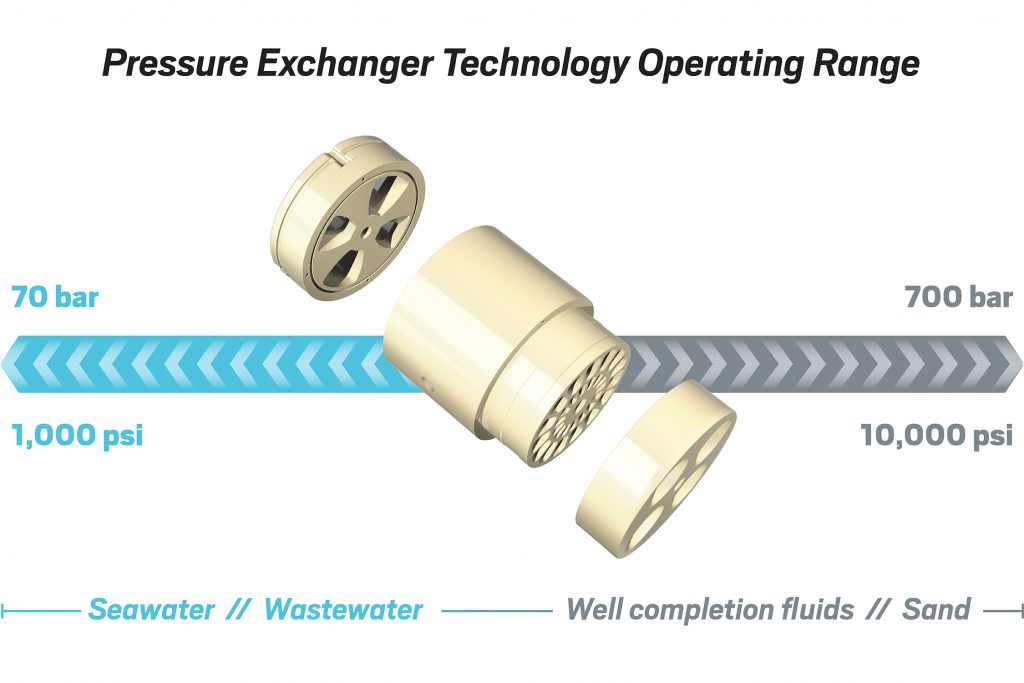

Our pressure exchanger technology is at the heart of many of our products. It is designed to make industrial fluid-flow processes more efficient and environmentally sustainable, lowering costs, saving energy, reducing waste, and minimizing emissions. This unique, versatile technology can operate in both high-pressure and low-pressure industrial fluid-flow systems and can handle a range of fluids from relatively clean to very dirty.

Today we are building new product applications on our pressure exchanger technology platform. We are also working to enlarge the technology’s operating range to expand and compress gas, which could expand the potential product applications of our pressure exchanger.

How It Works

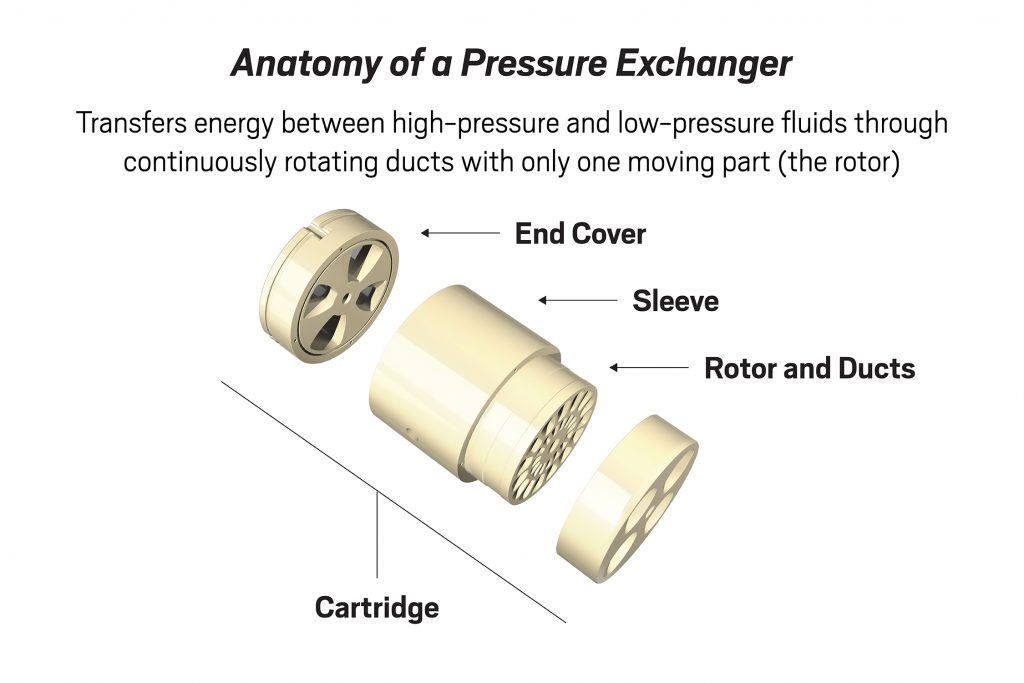

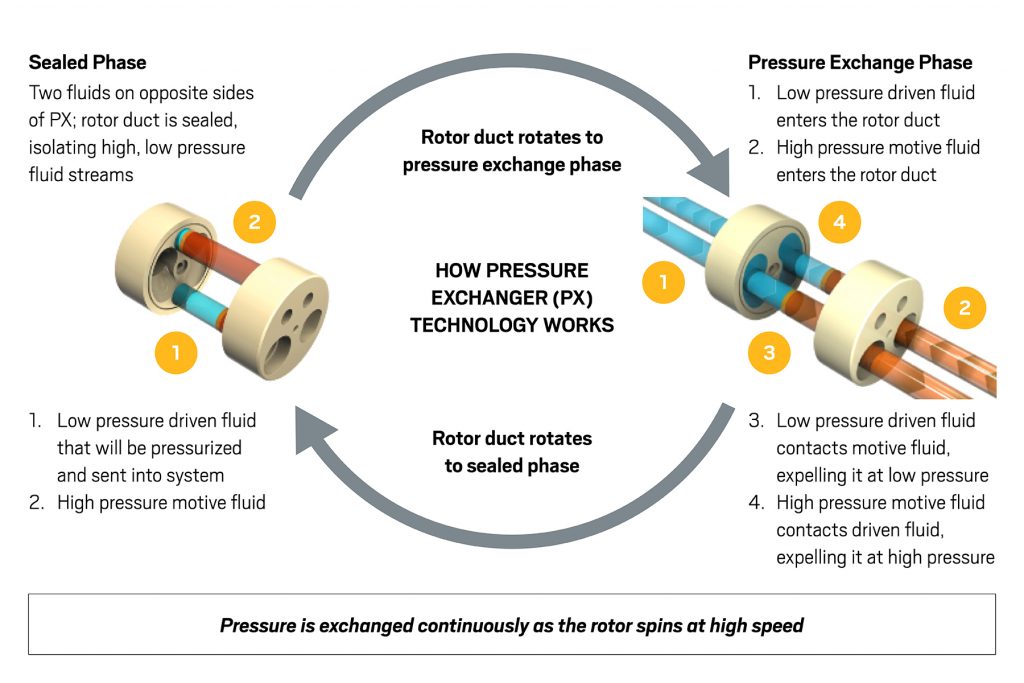

Pressure exchanger technology actions like a fluid piston, efficiently transferring energy between high-pressure and low-pressure liquid and/or gas through continuously rotating ducts. Key to the operation of a pressure exchanger is the micron-level clearance between the rotor and the pressure exchanger’s stationary components, including the sleeve and the end covers. Fluid circulating within this clearance acts as a bearing, minimizing friction for an extremely efficient exchange of pressure energy. Through our vertically integrated manufacturing, we ensure that all pressure exchangers, no matter the product application, meet our high standards for quality, durability, and reliability.

Accelerating Technical Innovation

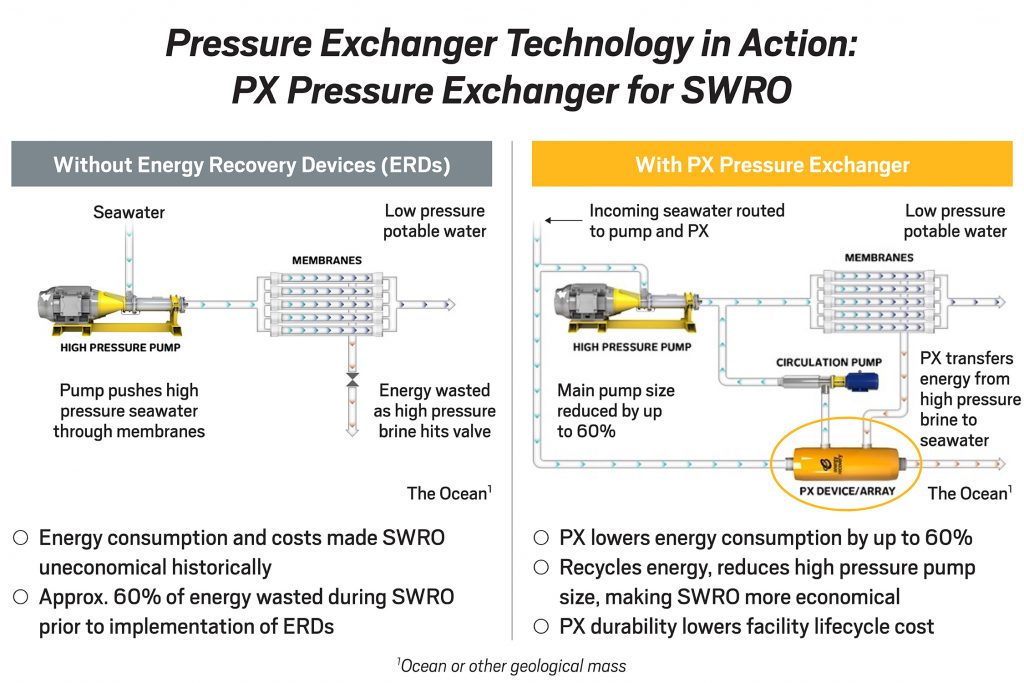

The initial product application of our technology was the PX Pressure Exchanger (PX). Delivering energy savings of up to 60% and efficiencies up to 98%, the PX revolutionized seawater reverse osmosis (SWRO) desalination and is today’s industry standard in energy recovery.

What began as a game-changing invention for desalination has grown into a global business advancing the environmental sustainability of customers’ operations in multiple industries. Today, we continue to push the boundaries of our core technology to handle different operating environments and industrial applications. With a robust pipeline of products in various stages of incubation, our team, from world-class engineers to manufacturing specialists, is committed to solving complex challenges for industrial fluid-flow markets worldwide.

Water Overview

The world’s need for clean water is intensifying, driven by population growth, industrialization, rapid urbanization, and climate change. According to United Nations estimates, global demand for water will surge 30% by 2050.

Oil & Gas Overview

With unique solutions from Energy Recovery, our customers in the oil and gas industry can improve productivity, increase efficiency, and reduce the environmental impact of their operations.