PX® Pressure Exchanger®

Best-in-class Energy Recovery

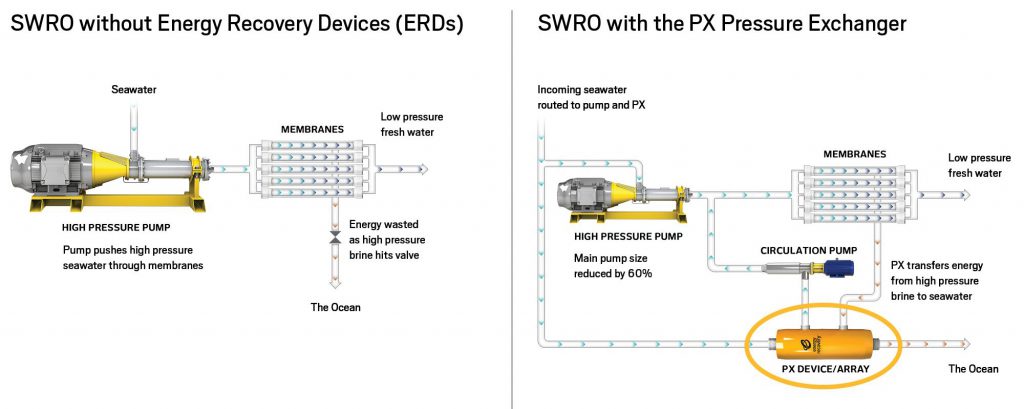

Our award-winning PX® Pressure Exchanger® (PX) family of products provides unmatched energy recovery for seawater reverse osmosis (SWRO) desalination systems. Large and small desalination projects around the world rely on our range of PXs to achieve optimal operations and maximum energy savings. Designed with only one moving part using highly engineered alumina ceramic, the PX stands up to the harshest of environments resulting in an unmatched life-cycle cost advantage.

Efficiency

Designed for maximum efficiency, the PX consumes no electrical power, enabling SWRO facilities to reduce their energy consumption by as much as 60%.

Performance

With no scheduled maintenance and proven performance for the long run, our PXs offer unbeatably low life-cycle costs.

Flexibility

Our range of PX capacities provides flexibility to optimize train size to specific project requirements, making the PX the ideal solution for new installations and retrofits alike.

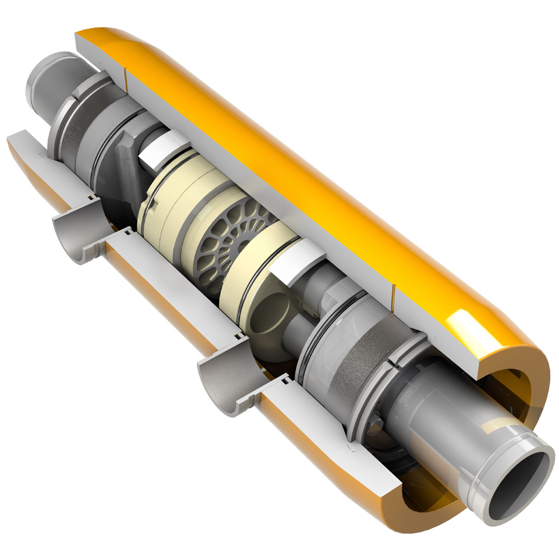

How the PX Pressure Exchanger Works

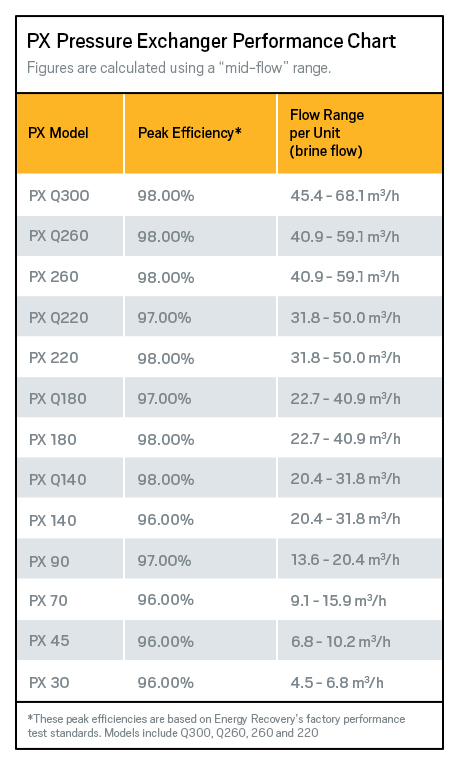

The PX Q Series is the gold standard in energy recovery devices. It includes the PX Q300, PX Q260, PX Q220, PX Q180 and PX Q140.

Quiet operation

PX Q devices offer operational sound levels below 79 decibels—comparable to a home vacuum cleaner—to enhance the safety of SWRO plant working environments through reduced audio levels.

Productive

PX Q devices provide reduction in fluid mixing, resulting in lower membrane feed salinity and pressure, and higher desalination system performance.

Scalable

Up to 40 parallel PX Q devices have been successfully installed in a single train, with 10 to 16 PXs commonly installed in parallel.

Efficient

PX Q devices perform with unparalleled efficiency—up to 98%.

The PX S series includes the following models: PX 90, PX 70, PX 45 and PX 30.

Flexibly-sized

PX S devices are designed to meet the needs of small- to medium-sized plants.

Modular Design

PX S devices can be installed in parallel according to specific plant needs.

Historically energy consumption and costs made SWRO uneconomical. With the PX Exchanger, up to 60% of that wasted energy can be recycled, driving substantial saving and emission reductions. In addition, the site and/or number of high pressure pumps can be decreased.

Long Lasting

Designed for a 30-year lifecycle

Resilient

No scheduled maintenance

Supported

Access to our support team of technical specialists to provide support at every phase of your project

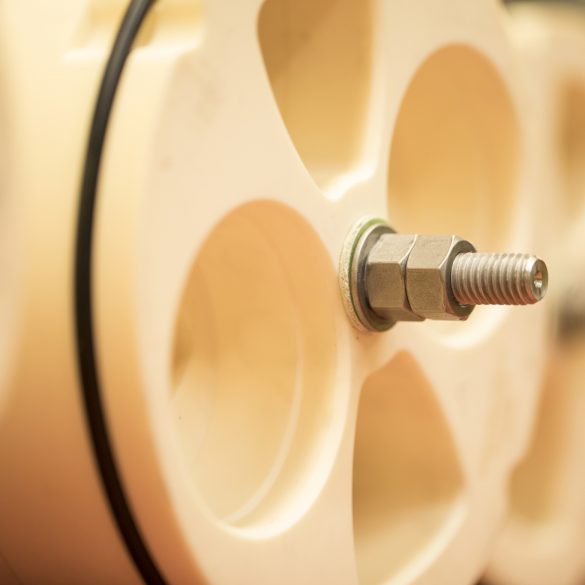

Superior Precision and Durability

The PX cartridges have only one moving part and are made with high-purity aluminum oxide ceramic. They’re corrosion-proof and three times more abrasion-resistant than steel. All that adds up to unmatched durability.

We design and manufacture ceramic PX components in-house at our California headquarters. This allows us to control the precision and quality of our core components down to the micrometer level, ensuring every PX device performs with maximum efficiency, durability, and reliability.

Contact us to discuss which PX is right for you.